Chip Forge & Double Brazing Hearth - DS430D

When space is limited, the Flamefast Combined Ceramic Chip Forge and Double Brazing Hearth* offers the solution. Based on well proven Flamefast technology, the unit consists of a ceramic chip forge and two brazing hearths, usually equipped with two Flamefast RF80 brazing torches.

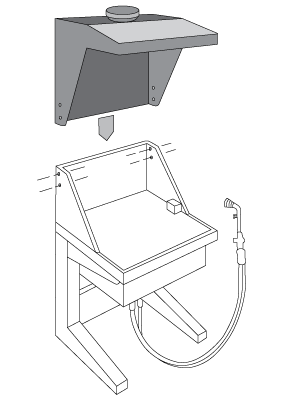

*Canopy & extraction optional , does not come as part of unit

Top Key Features

- Especially useful where space limitations are a consideration

- Easy to use especially for beginners

- Produces clean and consistent heat

- Can be run on either Natural Gas or LPG bottled gas

- UK Manufactured

Overview

When space is limited, the Flamefast Combined Ceramic Chip Forge and Double Brazing Hearth* offers the solution. Based on well proven Flamefast technology, the unit consists of a ceramic chip forge and two brazing hearths, usually equipped with two Flamefast RF80 brazing torches. The DS430D also has fail safe controls and runs on either Natural Gas or LPG bottled gas.

Key Features

- Especially useful where space limitations are a consideration

- Unit consists of a ceramic chip forge and two brazing hearth usually equipped with 2 Flamefast RF80 brazing torches

- Can be run on either Natural Gas or LPG bottled gas

- Can reach heats of 1200°C in under 10 min - ideal for forge/fire welding

- Produces a clean and consistent heat

- Easy to use especially for beginners

- Optional extras available

- UK Manufactured

Dimensions

| Width: | 1400 mm |

|---|---|

| Height: | 1080 mm |

| Depth: | 550 mm |

| Weight (Gross): | 133 kg |

| Height with Canopy: | 1800 mm with Varivac Extraction Canopy |

Technical Specifications

| Electrical: | 120 Watts - 220-240 volt single phase |

|---|---|

| Noise Level: | Whisper quiet air blower fan |

| Safety: | Appropriete PPE must be warn at all times when operating equipment Units must be installed & commissioned by Flamefast qualified engineers Fume Extraction is mandatory as per HSG258 / COSHH regulation. Please contact us for advice and cost. Push button no volt release starter Indicator status light |

| Warranty: | 2 Years |

PLEASE STATE GAS TYPE WHEN ORDERING

IMPORTANT NOTICE: ACCORDING TO THE HEALTH & SAFETY AT WORK ACT 1974, BS 4163 AND COSHH REGULATIONS IT IS MANDATORY THAT ALL FUMES MUST BE REMOVED AT SOURCE.

Performance

Forging Performance

| Gas Type | Rate | BTU / HRS | kW |

| Natural gas | 2.3 m3/h | 85 000 | 24.9 |

| Propane | 1.8 kg/h | 85 000 | 24.9 |

| Butane | 1.8 kg/h | 85 000 | 24.9 |

Brazing Performance

| Gas Type | Rate | BTU / HRS | kW |

| Natural gas | 4.36 m3/h | 160 000 | 46.9 |

| Propane | 3.3 kg/h | 160 000 | 46.9 |

| Butane | 3.39 kg/h | 160 000 | 46.9 |

Total Gas Performance

| Gas Type | Rate | BTU / HRS | kW | Pressure |

| Natural gas | 6.66m3/h | 245 000 | 71.8 | 20 mbar |

| Propane | 5.1 kg/h | 245 000 | 71.8 | 35 mbar |

| Butane | 5.19 kg/h | 245 000 | 71.8 | 28 mbar |

Standard Equipment - Forging

- Push-button no volt release starter

- Ceramic hearth

- Automatic safety check of controls and air fan

- Full manual control of hearth conditions

- Whisper quiet air blower fan

- Indicator status light

- Gas non-return valve

- 12.5 kg of ceramic chippings

- Operation/Instruction manual

- Side and rear heat shield

- Rake Iron

Standard Equipment - Brazing

- 2 asbestos-free heat resistant refractory hearths

- 4 full size Heat Reflective Blocks

- 8 half size Heat Reflective Blocks

- Push-button no-volt release starter

- 2 RF80 brazing torches

- Colour coded reinforced gas and air hoses

- Whisper quiet air blower fan

- Push button electronic ignition

- Auto gas leak proving system on start up

- Indicator status lights

- Gas non-return valve

- Operation/Instruction manual

Optional Extras

- RF10 fine jewellery torch

- 300mm revolving brazing table

- Brazing Kit

- *Fume extraction to meet HSG258 regulations

*Fume extraction is mandatory as per HSG258/ COSHH regulations. Please contact us for advice and cost

Varivac Extraction

The Varivac’s unique fume intake configuration captures all fumes and prevents any spillage. An electrical interlock prevents the use of linked equipment before the Varivac is switched ON.

It can be fitted to existing equipment if required with a choice of low level or high rise exhaust outlets.

To fit Varivac Extraction Place Varivac canopy around the outer rear top of the unit and bolt through the corresponding holes.