AUTOMATE-200 - basic principles of automation

AUTOMATE-200 is SMC International Training’s response to the increasing demand for the introduction of a technological culture in training centres

Top Key Features

- Modular training system

- Enjoyable and intuitive way of learning

- Includes up to 10 functional blocks

- Infinite number of configurations & activities

- Designed & built with industry relevant components

Overview

AUTOMATE-200 is SMC International Training’s response to the increasing demand for the introduction of a technological culture in training centres.

Using a recycling plant for solid urban waste as a reference, a fully modular design system has been developed for a training environment. The integration of the technologies in automated processes brings familiarization to the user of this fascinating world.

With this system, the student uses an integrated and motivating context to become familiar with technologies such as pneumatics, sensors, electric motors, PLCs, etc., in an enjoyable and intuitive way. Using completely industrial components we develop skills in analysis, troubleshooting, designing, creating technical documentation, setting up/

commissioning, understanding technical documentation, operation and programming.

AUTOMATE-200 includes up to ten functional blocks that can produce an infinite number of configurations, emulating different processes and making it possible to perform an endless number of activities with different

levels of difficulty.

The raw material used in the process includes parts with different colours (light/ dark), materials (plastic/ metal) and shapes (with or without hole). During the last phase of the process, the parts are sorted and stored in containers.

Key Features

- Modular training system

- Enjoyable and intuitive way of learning

- Includes up to 10 functional blocks

- Infinite number of configurations & activities

- Designed & built with industry relevant components

Dimensions

Technical Specifications

| AUTOMATE-200A 1200 x 865 x 350mm | MODULES | SENSORS (type & qty) | INPUT / OUTPUT |

| Vertical feeder Platform with part detector Colour detector Conveyor belt Belt drive Hole detector Material detector Roto-linear handling device with suction pads Part classifier Warehouse | Auto switch, Reed type (x10) Photoelectric (x1) Fiber optic (x2) Vacuum pressure switch (x1) Inductive (x1) | Digital 18/21 | |

| OTHER DEVICES (qty) | ACTUATORS (type & qty) | ||

| Manual control panel (x1) PLC control panel (x1) | Pneumatic linear (x9) Pneumatic rotary actuator (x1) DC motor (x1) Vacuum pad (x3) - Vacuum ejector (x1) | ||

| AUTOMATE-200B 900 x 580 x 1200mm | MODULES | SENSORS (type & qty) | INPUT / OUTPUT |

| Vertical feeder Platform with part detector Colour detector Conveyor belt Belt drive Hole detector Material detector Roto-linear handling device with suction pads Part classifier Warehouse | Auto switch, Reed type (x10) Photoelectric (x1) Fiber optic (x2) Vacuum pressure switch (x1) Inductive (x1) | Digital 19/19 | |

| OTHER DEVICES (qty) | ACTUATORS (type & qty) | ||

| Three-colour indication light (x1) Rolling table Folding control pane | Pneumatic linear (x9) Pneumatic rotary actuator (x1) DC motor (x1) Vacuum pad (x3) - Vacuum ejector (x1) | ||

| AUTOMATE-200C 645 x 760 x 290mm | MODULES | SENSORS (type & qty) | INPUT / OUTPUT |

| Vertical feeder Roto-linear handling device with pneumatic gripper Conveyor belt Material detector Presence detector End of conveyor belt detector Part sorting | Auto switch, Reed type (x4) Photoelectric (x1) Fiber optic (x3) Inductive (x1) Capacitive (x1) Micro-switch (x1) | Digital 20/16 | |

| OTHER DEVICES (qty) | ACTUATORS (type & qty) | ||

| Step by step driver servo Vcc (x1) | Pneumatic linear (x2) Pneumatic gripper (x1) Step by step motor servo Vcc (x1) DC motor (x1) Solenoid (x1) | ||

Relevant Technologies

- Pneumatics

- Vacuum

- Electric motors

- Sensors

- Programmable controllers

- Manipulators

- Automated systems

Versions

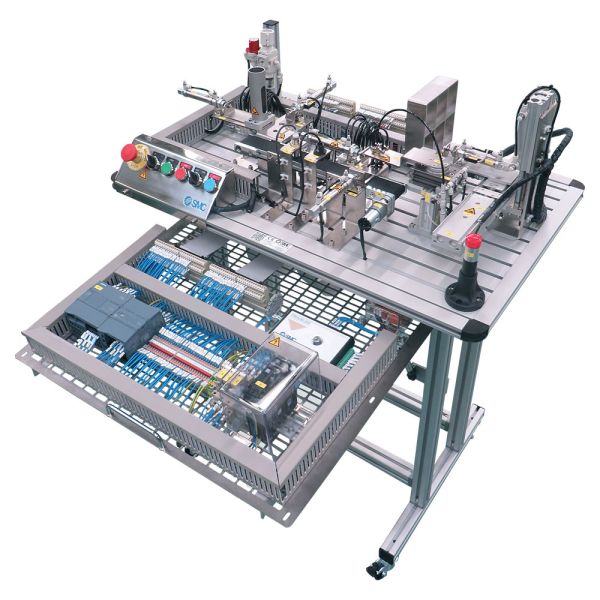

AUTOMATE-200A: Instant connection wiring

It has two control panels, manual and via a PLC, prepared for rapid connection to the functional module

AUTOMATE-200B: Take it wherever you want

This version, in addition to including the functional modules of the 200A version, is mounted on a trolley base with a fold-away control panel for the PLC and all electrical connections

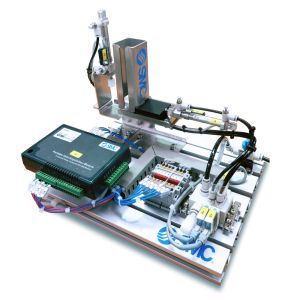

AUTOMATE-200C: The most compact in the range

Where space is at a premium, the compact version of AUTOMATE-200 includes all the essential AUTOMATE-200 features in a small footprint

Common elements in all versions:

Power supply, air treatment unit, anodised aluminium structure, control keypad, solenoid valve block, labels for cables, speed controllers, control PLC*, user manual and practice manual and Multimedia CD.

*Options: PLC Omron, Allen Bradley, Mitsubishi or Siemens.

Optional Extras

PROGRAMMING TOOLS

The programming tools comprise the appropriate programming software and cables for the chosen PLC.

SCADA: Supervisory Control and Data Acquisition

This is an industrial standard software application, making it easier to remotely supervise and control processes from a computer screen

AUTOMATE-200 application for autoSIM-200

We have a 3D application where users can simulate, supervise and control AUTOMATE-200 from an autoSIM environment

* autoSIM is required.

** Not available in AUTOMATE-200C version Troubleshooting simulation system for Automate-200

Troubleshooting simulation system for AUTOMATE-200

The troubleshooting simulation system TROUB-200 can be included in the AUTOMATE-200A and AUTOMATE-200B versions, which generates up to 16 different breakdowns to be diagnosed by the user.