ATM-200 - Automation training system

ATM-200 is a set of 3 separate stations, fully assembled, built entirely of industrial components. The set includes a 3D application of each station to simulate and control them from autoSIM-200 enviroment.

Top Key Features

- All the stations include autoSIM-200 simulation software (1 license each)

- Simulate, control and supervise actual automated processes from a virtual environment

- Include 3D models from the real process

Overview

ATM-200 is a set of 3 separate stations, fully assembled, built entirely of industrial components. The set includes a 3D application of each station to simulate and control them from autoSIM-200 enviroment.

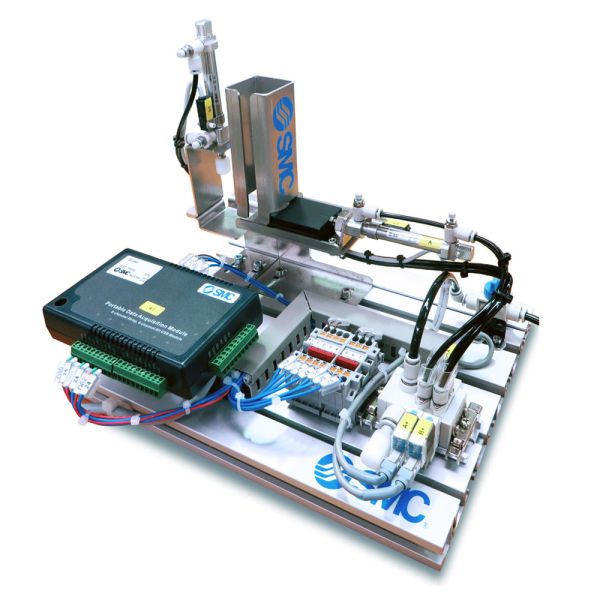

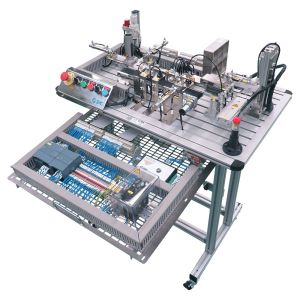

The 3 stations (stacking magazine station, pneumatic handling station and conveyor station) are supplied fully assembled in an anodized aluminum structure of 200x300mm dimensions. Each station inputs and outputs are connected to an interface for their control using simulation software on a PC (PC not included).

Key Features

- All the stations include autoSIM-200 simulation software (1 license each)

- All the stations include the 3D application for simulate and control the station from autoSIM-200 environment (1 license each)

- Simulate, control and supervise actual automated processes from a virtual environment

- Include 3D models from the real process

- Compatible with automation application simulator software autoSIM-200

- Access to the virtual PLC programming editor integrated in autoSIM-200

- Access to the table of symbols from the virtual PLC

- Access to the libraries and to the simulation panel for components in pneumatics, electro-pneumatics, hydraulics, electro-hydraulics and electrics

- Independent window with 3D model

Dimensions

Technical Specifications

Available Options

| OPTIONS | DESCRIPTION | CODE |

| ATM 201 + ATM 202 + ATM 203 | Stacking magazine station + Pneumatic handling station + Conveyor station | SAI7299 |