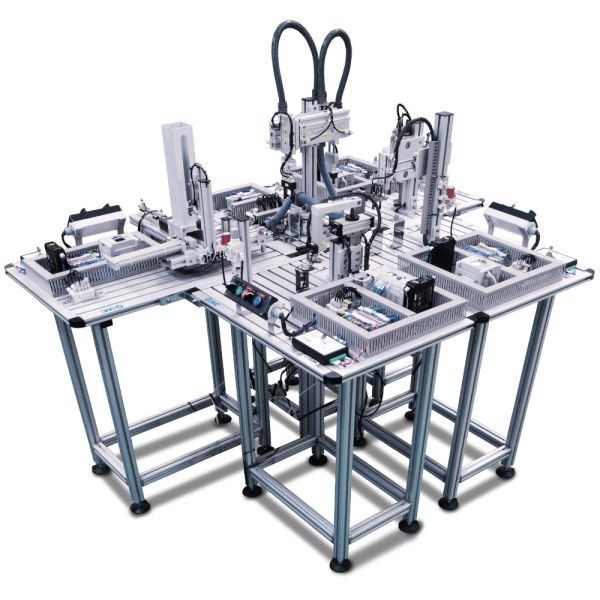

MAS-200 - Modular assembly system

MAS-200 is a modular training system which emulates a real industrial assembly process, incorporating the technologies required by today’s automated industry. The complete system consists of five stations. The various parts of the final assembled product (base, bearing, shaft and lid) are fed into four of the stations. The fifth station is located between the others and is responsible for transferring and assembling the parts.

Top Key Features

- Modular training system

- Emulates a real industrial assembly process

- 5 independent stations

- Completely autonomous stations for vast range of options

Can form a complete manufacturing cell

Overview

MAS-200 is a modular training system which emulates a real industrial assembly process, incorporating the technologies required by today’s automated industry. The complete system consists of five stations. The various parts of the final assembled product (base, bearing, shaft and lid) are fed into four of the stations. The fifth station is located between the others and is responsible for transferring and assembling the parts.

The modular features of the equipment allow a vast range of options since the stations are completely autonomous, but can be assembled to form a complete manufacturing

cell. The design of the MAS-200 allows simple and quick extraction of the stations, assisting individual work with each of them. All the components of which the MAS-200 is comprised are used in industry, allowing the user to gain detailed knowledge of the technologies currently used in automated industry.

Key Features

- Modular training system

- Emulates a real industrial assembly process

- 5 independent stations

- Completely autonomous stations for vast range of options

- Can form a complete manufacturing cell

- Simple and quick extraction of stations

- Designed & built with industry relevant components

Dimensions

Technical Specifications

| MAS-201 843 x 580 x 1300mm | MODULES | SENSORS (type & qty) | INPUT / OUTPUT |

| Part feed Position verification Displacement Incorrect part rejection | Auto switch, Reed type (x4) Inductive (x1) | Digital 9/5 | |

| OTHER DEVICES (qty) | ACTUATORS (type & qty) | ||

| Breakdown simulation system (x1) | Pneumatic linear (x4) | ||

| MAS-202 743 x 580 x 1300mm | MODULES | SENSORS (type & qty) | INPUT / OUTPUT |

| Part transfer | Auto switch, Reed type (x4) Vacuum pressure switch (x1) | Digital 9/5 | |

| OTHER DEVICES (qty) | ACTUATORS (type & qty) | ||

| Breakdown simulation system (x1) Vacuum pad(x3)-Vacuum ejector (x1) | Pneumatic linear (x2) | ||

| MAS-203 743 x 580 x 1200mm | MODULES | SENSORS (type & qty) | INPUT / OUTPUT |

| Part transfer | Auto switch, Reed type (x3) Barrier type photocell (x2) | Digital 9/4 | |

| OTHER DEVICES (qty) | ACTUATORS (type & qty) | ||

| Breakdown simulation system (x1) | Pneumatic rotary actuator (x1) Pneumatic gripper (x1) | ||

| MAS-204 743 x 580 x 1120mm | MODULES | SENSORS (type & qty) | INPUT / OUTPUT |

| Part transfer | Auto switch, Reed type (x4) Fiber optic photocell (x2) Solid state (x2) | Digital 12/4 | |

| OTHER DEVICES (qty) | ACTUATORS (type & qty) | ||

| Breakdown simulation system (x1) | Pneumatic rotolinear (x1) Pneumatic gripper (x1) | ||

| MAS-205A 743 x 400 x 1320mm | MODULES | SENSORS (type & qty) | INPUT / OUTPUT |

| Handling parts by external gripper Handling parts by internal gripper Dividing plate | Auto switch, Reed type (x10) | Digital 15/10 | |

| OTHER DEVICES (qty) | ACTUATORS (type & qty) | ||

| Breakdown simulation system (x1) Bar code reader (x1) | Pneumatic linear (x8) Pneumatic gripper (x2) | ||

| MAS-205B 743 x 580 x 1550mm | MODULES | SENSORS (type & qty) | INPUT / OUTPUT |

| Robot | Digital 7/6 | ||

| OTHER DEVICES (qty) | ACTUATORS (type & qty) | ||

| Robot controller unit (x1) Programming console (x1) | Six axis robot (x1) Pneumatic gripper (x2) | ||

Relevant Technologies

- Electrical panel

- Pneumatics

- Vacuum

- Sensors

- Identification system

- Programmable controllers

- Manipulators

- Robotics

- Industrial communication

- SCADA / HMI

- Automated systems

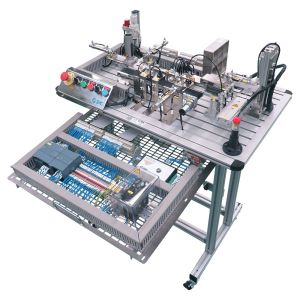

MAS-201: Feeding base with detection & ejection of incorrect parts

This station feeds the base which supports the final assembled product

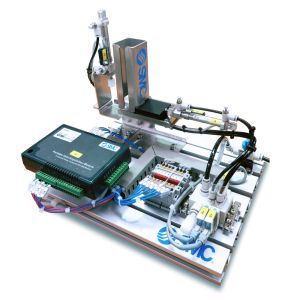

MAS-202: Positioning of the lid

This station allows the insertion of a lid into the workpiece

MAS-203: Insertion of the bearing

The third MAS-200 station feeds a bearing

MAS-204: Insertion of the shaft

The FAS-204 station measures the height of the bearing provided by the previous station

MAS-205A & B: Transfer of the parts

This station emulates the pressing of the bearing against the base

Common element in all stations:

Power supply, air treatment unit, anodised aluminium structure, control keypad, solenoid valve block, labels for cables, electric connection terminals, speed controllers, control PLC* and user manual and practice manual.

*Options: PLC Siemens, Omron, Mitsubishi, Allen Bradley or without PLC.

Optional SCADA Tool

The MAS-200 system includes an optional SCADA tool which enables:

- Access to the status of the various field devices.

- Display, management and storage in the PC of information collected during the process.

- Control and modification of the process in real time.

- Display of the various phases of the process via a graphical interface.

- Recognition of alarms in the event of system failures.

- Generation of data logs and statistical data.