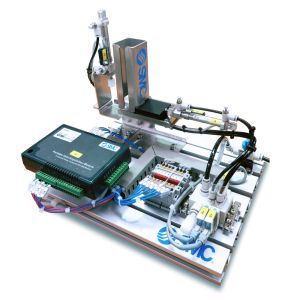

FMS-200 Flexible integrated assembly system

The modular features of this flexible automation cell enables the introduction of variations in its stations so that they adapt to the different requirements of companies and training centres. From a simple configuration of one station only (working fully autonomously) to a complex configuration with eight or ten stations, the possibilities are endless.

Top Key Features

- Simple or complex configuration

- Designed & built with industry relevant components

- Includes breakdown simulation system

- Stations adapt to a wide variety of assemblies

- 8 to 10 stations

- 24 different assemblies

Overview

The modular features of this flexible automation cell enables the introduction of variations in its stations so that they adapt to the different requirements of companies and training centres. From a simple configuration of one station only (working fully autonomously) to a complex configuration with eight or ten stations, the possibilities are endless.

In addition, it facilitates a staggered investment, i.e. starting with an initial simple configuration which can be easily enhanced by adding workstations. All the components in the FMS-200 are used in industry, so that the user can work with real elements at all times making the learning process more meaningful. The system includes a whole series of feeding, handling, verification and loading operations etc. carried out using components from different technologies (pneumatics, hydraulics, sensors, robotics, communications, control and HMI).FMS-200 includes the breakdown simulation system which generates up to 16 different breakdowns to be diagnosed by the user.

The different process stations assemble a turning mechanism. To provide the system with greater flexibility, stations adapt to a wide variety of assemblies, introducing variations in the materials, colours and part sizes. The combination of all these possibilities means that a total of 24 different assemblies can be obtained enabling the use of production management strategies. The control panel is completely modular and can be rapidly disassembled

Key Features

- Simple or complex configuration

- Facilitates staggered investment

- Designed & built with industry relevant components

- Includes breakdown simulation system

- Stations adapt to a wide variety of assemblies

- 8 to 10 stations

- 24 different assemblies

- Modular control panel that’s easy to disassemble

Dimensions

Technical Specifications

| FMS-201 900 x 580 x 1480mm | MODULES | SENSORS (type & qty) | INPUT / OUTPUT |

| Base feeding Position verification Displacement Rejection of incorrect base Insertion on pallet | Auto switch, Reed type (x8) Vacuum pressure switch(x1) Inductive (x1) | Digital 14/10 | |

| OTHER DEVICES (qty) | ACTUATORS (type & qty) | ||

| Vacuum pad(x4)-Vacuum ejector(x1) Three-colour indication light (x1) Breakdown simulation system (x1) | Pneumatic linear (x6) | ||

| FMS-202 900 x 580 x 1430mm | MODULES | SENSORS (type & qty) | INPUT / OUTPUT |

| Bearing feeding Transfer to the measuring station Height measuring Bearing insertion | Auto switch, Reed type (x10) Microswitch (x1) Linear potentiometer (x1) | Digital 15/13 Analog 1/0 | |

| OTHER DEVICES (qty) | ACTUATORS (type & qty) | ||

| Three-colour indication light (x1) Breakdown simulation system (x1) | Pneumatic linear (x4) Pneumatic gripper (x2) Pneumatic rotolinear (x1) Pneumatic rotary actuator (x1) | ||

| FMS-203 900 x 580 x 1400mm | MODULES | SENSORS (type & qty) | INPUT / OUTPUT |

| Insertion / extraction of the workpiece Press feeding Bearing pressing | Auto switch, Reed type(x11) Vacuum pressure switch(x1) Security magnetic (x1) | Digital 16/10 | |

| OTHER DEVICES (qty) | ACTUATORS (type & qty) | ||

| Vacuum pad (x4) - Vacuum ejector (x1) Breakdown simulation system (x1) Safety relay (x1) Hydraulic equipment (x1) Frequency converter (x1) | Pneumatic rotary actuator (x1) Pneumatic linear (x3) Hydraulic linear (x1) | ||

| FMS-204 900 x 580 x 1800mm | MODULES | SENSORS (type & qty) | INPUT / OUTPUT |

| Dividing plate Shaft feeding Shaft height measuring Position shaft in the correct position Shaft material detection Removal of incorrect shaft Insertion of the shaft in the assembly | Auto switch, Reed type(x12) Inductive (x1) Capacitive (x1) Vacuum pressure switch(x2) | Digital 20/16 | |

| OTHER DEVICES (qty) | ACTUATORS (type & qty) | ||

| Three-colour indication light (x1) Vacuum pad(x2)-Vacuum ejector(x2) Breakdown simulation system (x1) | Pneumatic rotolinear (x1) Pneumatic linear (x9) Pneumatic rotary actuator (x1) Pneumatic gripper (x1) | ||

| FMS-205 900 x 580 x 1400mm | MODULES | SENSORS (type & qty) | INPUT / OUTPUT |

| Dividing plate Lid feeding Loading station Material detection Lid measuring Removal of the incorrect lid Lid insertion | Auto switch, Reed type(x13) Inductive (x1) Micro-switch (x1) Capacitive (x1) Photoelectric (x1) Linear encoder (x1) Vacuum pressure switch(x1) | Digital 24/16 | |

| OTHER DEVICES (qty) | ACTUATORS (type & qty) | ||

| Breakdown simulation system (x1) Three-colour indication light (x1) Vacuum pad(x3)-Vacuum ejector(x1) Pressure regulator (x1) | Pneumatic linear (x7) Pneumatic roto-linear (x2) Pneumatic gripper (x2) | ||

| FMS-206 900 x 580 x 1930mm | MODULES | SENSORS (type & qty) | INPUT / OUTPUT |

| Screw feeding Transfer Screw insertion handling device | Auto switch, Reed type (x6) Fibre optic photocell (x1) Solid state auto switch (x2) | Digital 13/9 | |

| OTHER DEVICES (qty) | ACTUATORS (type & qty) | ||

| Breakdown simulation system (x1) Three-colour indication light (x1) | Pneumatic linear (x5) Pneumatic gripper (x1) | ||

| FMS-207 900 x 580 x 1500MM | MODULES | SENSORS (type & qty) | INPUT / OUTPUT |

| Shaft and lid stores Robot tools Robot arm and controller components | Auto switch, Reed type(x1) Security magnetic (x1) | Digital 12/12 | |

| OTHER DEVICES (qty) | ACTUATORS (type & qty) | ||

| Robot controlling unit (x1) Robot programming console (x1) Security lock (x1) Safety relay (x1) | Electric screwing tool (x1) Pneumatic gripper (x1) 6 axis robot (x1) | ||

| FMS-208 900 x 580 x 1500mm | MODULES | SENSORS (type & qty) | INPUT / OUTPUT |

| Vertical shaft Positioning axes | Auto switch, Reed type(x2) Digital vacuum pressure switch(x1) Security magnetic (x1) | Digital 16/15 | |

| OTHER DEVICES (qty) | ACTUATORS (type & qty) | ||

| Vacuum pad(x4)-Vacuum ejector(x1) Servo-controller (x2) Driver programming software and cable (x1) Safety relay (x1) Security lock (x1) | Pneumatic linear (x1) Servo-controlled linear actuators (x2) | ||

| FMS-209 900 x 580 x 1500mm | MODULES | SENSORS (type & qty) | INPUT / OUTPUT |

| Insertion/extraction handling device Electric shaft Oven | Auto switch, Reed type (x7) Vacuum pressure switch(x1) PT100 temperature probe(x1) Security magnetic (x1) | Digital 23/24 | |

| OTHER DEVICES (qty) | ACTUATORS (type & qty) | ||

| Vacuum pad(x4)-Vacuum ejector(x1) Servo-controller (x2) Potentiometer (dimmer) (x1) PID temperature controller (x1) Safety relay (x1) Driver programming software and cable (x1) Security lock (x1) | Pneumatic linear (x4) Pneumatic rotary actuator (x1) Servo-controlled linear actuator with brake (x2) 90º track AC motor with analogue control (x1) | ||

| FMS-210 900 x 580 x 1500mm | MODULES | SENSORS (type & qty) | INPUT / OUTPUT |

| Insertion/extraction handling device Revolving table Artificial vision system Evacuation of the faulty product in process | Auto switch, Reed type (x7) Vacuum pressure switch(x2) Artificial vision camera (x1) | Digital 18/18 | |

| OTHER DEVICES (qty) | ACTUATORS (type & qty) | ||

| Vacuum pad(x8)-Vacuum ejector(x2) Servo-controller (x1) Vision processing unit (x1) Breakdown simulation system (x1) Vision system programming software and cable (x1) | Pneumatic rotary actuator (x1) Pneumatic linear (x2) Electric turntable (x1) | ||

| LINEAR TRANSFER 4250 x 700 x 1040mm | MODULES | SENSORS (type & qty) | INPUT / OUTPUT |

| Linear transfer | Auto switch, Reed type (x4) Inductive (x24) Micro-switch (x8) Capacitive (x2) | Digital 43/21 | |

| OTHER DEVICES (qty) | ACTUATORS (type & qty) | ||

| Frequency converter (x1) Modules for field bus (x10) | Pneumatic rotary actuator (x1) Pneumatic linear (x13) | ||

| MODULAR TRANSFER 1000 x 210 x 970mm | MODULES | SENSORS (type & qty) | INPUT / OUTPUT |

| Modular transfer | Inductive (x3) Micro-switch (x1) | Digital 4/2 Digital 4/3 * Digital 4/4 ** | |

| OTHER DEVICES (qty) | ACTUATORS (type & qty) | ||

| Modules for field bus (x1) | DC motor (x1) Pneumatic linear (x1/x2*/x2**) Pneumatic rotary actuator (x1)** | ||

* Only in modular transfer for FMS-202 and FMS-207 stations.

** Only in modular transfer for FMS-206 station.

FMS-201: Body supply

In this station, the base which acts as the support to the assembled product is fed

FMS-202: Bearing selection/ supply

In this station, the bearing is assembled in the base housing. Bearings with different heights can be selected

FMS-203: Hydraulic press

This phase of the press fits bearing inserted in the previous station using a hydraulic ram

FMS-204: Shaft selection/ supply

The shaft is inserted into the product. There are two types of shafts manufactured from different materials: aluminium and nylon.

FMS-205: Cover selection/ supply

This station inserts a lid on the set of parts. There are 6 different types of lids: depending on material, colour and height

FMS-206: Screws supply

This station inserts four screws in the base of the workpiece

FMS-207: Robotized screwing

The seventh FMS-200 station integrates robotics technology. The robot screws in the four screws inserted in the product by the previous station. In addition, shaft and lid assembly exchange operations can be carried out.

FMS-208: Automatic warehouse

This station stores the finished products

FMS-209: Paint drying in oven

During this phase of the assembly a paint drying process is simulated using a polycarbonate oven

FMS-210: Quality control using artificial vision

The incorporation of this station in the FMS-200 family represents the integration of the artificial vision technology via artificial vision. The workpiece is transferred to the inspection position in which an artificial vision camera examines it against a known good part. Size, shape, missing holes can all be verified.

The transfer system:

In order to provide the most flexible solutions for our customers needs, FMS-200 is available in two different versions: with a four meters long linear transfer system or with modular transfer sections coupled to each station. The two options are described below.

Linear transfer

This is a rectangular transfer system through on which pallets containing the workpiece circulate around the stations

Modular transfer

In this FMS-200 version, each of the stations includes an individual transfer section. Multiple combinations of layouts can be developed, with the option of joining stations at 90º or 180º (section in curve, straight section).

Common element in all stations: Power supply, anodised aluminium structure, control keypad, solenoid valve block, labels for cables, electric connection terminals, speed controllers, air treatment unit, control PLC* and user manual and practice manual.

* Options: PLC Siemens, Omron, Mitsubishi, Allen Bradley, Schneider or without PLC.

FMS-200

FMS-200 is a totally modular and flexible didactic system, developed for an integral training in industrial automation. The technologies integrated and the assembling process with several variants, allow the user to develop the professional skills required by the automated industry of today and tomorrow. The successful experience of the FMS-200 guarantees that it is training equipment of exceptional quality and reliability used by companies and teaching centers throughout the world.